Kota Cutting Tools: Precision Cutting Tools Manufacturer in Malaysia

Engineering and metalworking machine tools manufacturer in Malaysia since 30 years ago.

Leading Cutting Tools Manufacturer in Malaysia Since 1994

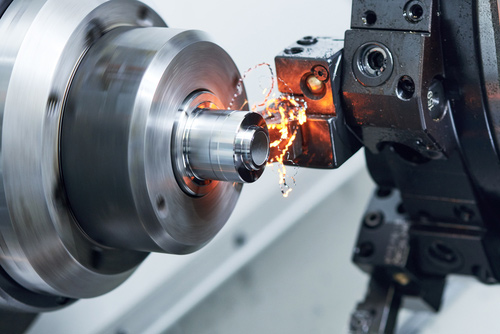

Strategically located in Puchong, Malaysia. Kota Cutting Tools is a top manufacturer of cutting tools in Malaysia. We offer a comprehensive range of high-precision cutting tools and solutions, including cutting, threading, chamfering, and deburring tools. We set ourselves apart by providing the best quality cutting tools at competitive prices, tailored to meet the demands of industries across Malaysia.

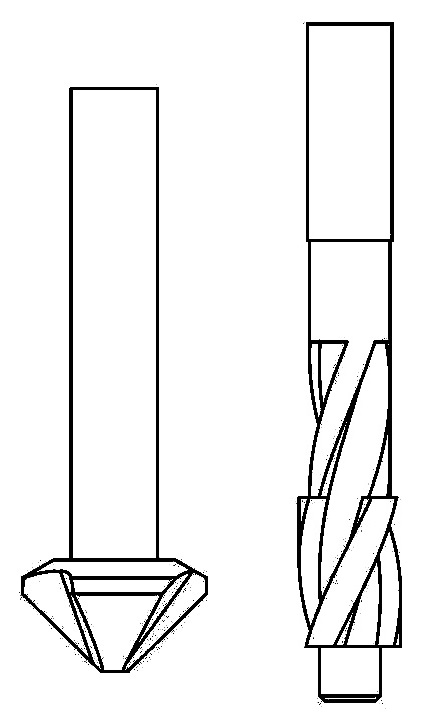

Our High-End Cutting Tools

A wide selection of cutting tools catering to the diverse needs of industries in Malaysia. Whatever your application, we have the perfect tool for you.

Kota Cutting Tools: The Perfect Cutting Tools for Your Industry

Brands We Carry

We supply high-quality cutting tools that can withstand harsh environments while delivering the precision needed to achieve exceptional results.

Brands We Carry

Acquire Premium Quality Cutting Tools at Exceptional Prices with Kota Cutting Tools

Our cutting tools are expertly manufactured and rigorously tested by our technical team to

enhance your machining performance and take your business to new heights.

Frequently Asked Questions

What types of cutting tools do Kota Cutting Tools offer?

As a leading cutting tools manufacturer in Malaysia, Kota Cutting Tools provides a wide range of cutting tools tailored to the needs of various industries, including drill bits, end mills, machine taps, and machine reamers.

Do you provide custom cutting tool solutions?

Yes. As a trusted supplier of cutting tools in Malaysia, we work closely with clients to design solutions tailored to their unique applications. Contact us to discuss your project, and our team will assist in designing a solution tailored to your needs.

Can you recommend the right cutting tool for my application?

With over 30 years of experience as a cutting tools manufacturer in Malaysia, Kota Cutting Tools has the expertise to help you choose the right tools. If you face difficulty choosing the right tools for your machine, talk to our engineering experts. We’ll ensure you get the most suitable tools for your specific requirements.

Is HSS or carbide better for cutting tools?

HSS cutting tools are less expensive than carbide cutting tools. They maintain a significantly sharper edge, making them suitable for reducing materials that carbide cannot handle effectively. Additionally, HSS tools have a simpler sharpening process compared to carbide tools, and they allow for higher-speed cutting, which helps reduce production cycle times.

Carbide cutting tools, on the other hand, operate at cutting speeds 6–8 times faster than HSS tools. They produce high-quality surface finishes, are highly resistant to thermal deformation, and are ideal for demanding applications.

Why do businesses in Malaysia choose Kota Cutting Tools as their cutting tools supplier?

Businesses across Malaysia trust Kota Cutting Tools because we offer high-quality cutting tools at competitive prices. Our tools are designed to ensure efficiency and success in operations, and we carry reputable brands known for their durability and precision. As a dedicated cutting tools supplier, we prioritize customer satisfaction in every partnership.

How long can a good-quality cutting tool last?

The lifespan of cutting tools depends on their construction, design, and application. Some tools are designed for short-term use, while others are built for long-term durability. Investing in high-quality cutting tools from a trusted manufacturer can minimize downtime, extend tool life, and ensure a more reliable and cost-effective workflow.

Do you provide nationwide delivery?

Yes, we deliver cutting tools throughout Malaysia and internationally. As a reliable cutting tools supplier, we ensure your orders are carefully packed and arrive promptly in excellent condition. Contact our customer service team for more information about delivery options.

My tools wear out too fast. What should I do?

Tool wear is inevitable, but excessive wear can disrupt your operations. To extend the life of your cutting tools, choose products from a reliable cutting tool manufacturer in Malaysia.

Proper tool selection, material optimization, and wear mitigation strategies are key to reducing costs and improving performance. Contact us for advice on how to manage tool wear effectively.

I need cutting tools urgently. Do you have ready stock?

We maintain ready stock for most cutting tools. However, some items may occasionally be out of stock. We recommend checking availability with our sales team to ensure we can meet your urgent requirements.