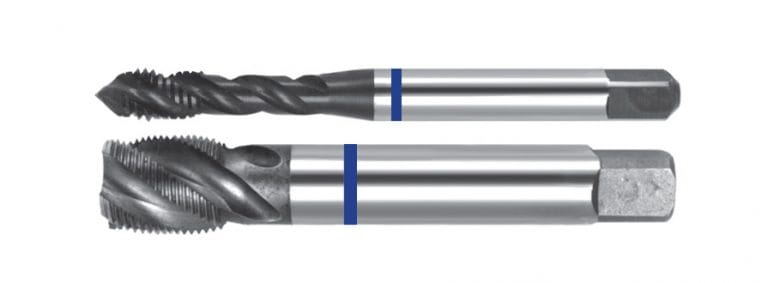

Tap Comparison: Machine Tap vs Hand Tap

Threading is a fundamental process in metalworking that creates helical ridges (threads) inside a hole, allowing for the secure attachment of fasteners like screws and bolts. The primary tool used for creating internal threads is a tap.

Two common categories of taps used in the industry are hand taps and machine taps.

The terminology “hand tap” and “machine tap” originated in the early 1800s when most threading applications were performed manually. Despite advancements in manufacturing technology, these legacy terms remain in use today, though they can be somewhat misleading about a tap’s modern method of use.

This comprehensive guide explores the differences between hand taps and machine taps, their respective applications in metalworking, and guidelines for choosing the right tap for specific projects.

Also read: A Complete Overview of the Best Thread Taps for Machinists and DIY Enthusiasts

What Are Hand Taps?

Hand taps are traditionally straight-fluted taps with a standard general-purpose length. They were originally designed to be used manually with a tap wrench, though they can also be used with machines [2]. The term “hand tap” has been applied to fractional-size taps by some manufacturers, though most don’t limit the description to fractional sizes.

Design Features

Straight Flutes: Hand taps typically have straight flutes that run parallel to the tap’s axis. These flutes provide space to accommodate chips created during the cutting process.

Thread Form: The threads on a hand tap are designed to create a complete thread profile in a single pass, making them suitable for general-purpose threading.

Chamfer Length: Hand taps often come in sets with different chamfer lengths [4]

- Taper Tap: Features a long chamfer with gradual tapering and several incomplete threads. Ideal for starting a thread cleanly and ensuring easy alignment. Typically identified with one ring.

- Intermediate Tap: Has a medium chamfer length with more fully formed teeth than a taper tap. It continues the threading process once the thread has been started. Commonly marked with two rings.

- Finishing Tap: Contains a very short chamfer, usually 1–2 threads, allowing threads to be cut close to the bottom of blind holes. This tap is generally unmarked.

Applications

Hand taps excel in applications where:

- Precise control over the threading process is required

- Lower cutting speeds are acceptable

- Difficult materials or conditions make machine tapping challenging

- Repairs or field work need to be performed without power tools

Usage Technique

When using hand taps, the process typically involves:

- Drilling a pilot hole slightly larger than the minor diameter of the thread

- Starting with a taper tap (if using a set)

- Using a tap wrench to slowly turn the tap clockwise while applying downward pressure

- Regularly reversing direction to break chips

- Using cutting fluid to reduce friction and improve thread quality

- Following with plug and bottoming taps as needed (if using a set)

What Are Machine Taps?

Machine taps are designed with features that optimize their performance when used at higher speeds with power tools or CNC machines [2]. According to industry sources, machine taps were developed to address the challenges of chip evacuation that became more difficult to control as tapping speeds increased with mechanization.

Design Features

Flute Geometry: The defining characteristic of machine taps is their flute geometry, designed to direct the flow of chips out of the hole. Two common designs are:

- Spiral Point Taps: Have a point with angled flutes that push chips forward, making them ideal for through holes.

- Spiral Flute Taps: Feature flutes that spiral around the body, pulling chips upward and out of the hole, making them suitable for blind holes.

Chamfer: Machine taps typically have a shorter chamfer length than hand taps, allowing them to cut threads more quickly.

Relief Angles: Machine taps often have modified relief angles to withstand the higher cutting forces encountered at increased speeds.

Coolant Holes: Modern machine taps may include internal coolant holes that provide lubrication directly to the cutting edges.

Applications

Machine taps are preferred in applications where:

- High production volumes require faster threading

- Automated or semi-automated operations are used

- Consistent thread quality across multiple workpieces is critical

- Through holes need efficient chip evacuation

- Materials with good machinability are being worked

Usage Technique

When using machine taps, the process typically involves:

- Securing the tap in a machine collet or tap holder

- Programming the correct speeds and feeds for the specific material

- Using appropriate cutting fluid or coolant

- Setting the machine to either use a tension-compression tap holder or a rigid tapping cycle

- Monitoring the process to ensure proper chip evacuation and thread quality

What Are The Differences Between Hand Taps & Machine Taps?

Hand taps and machine taps are both used to create internal threads in pre-drilled holes, but they differ significantly in operation and application.

| Category | Hand Taps | Machine Taps |

| Operation Method | Operated manually using a tap wrench | Used with powered tapping machines, CNC machines, or drill presses |

| Threading Process | Performed in stages using taper, intermediate, and finishing taps | Cuts threads in a single operation |

| Speed | Slower | Faster and more efficient |

| Precision Requirement | Requires careful manual alignment with hole axis | Requires rigid, accurate machine guidance |

| Risk of Breakage | Lower due to staged cutting | Higher due to increased cutting force and speed; fragile |

| Best Use Case | Low-volume production, repair work, fieldwork | Medium- to high-volume production |

| Material Suitability | Works well with machinable materials | Available in designs for various materials, hole types, and thread profiles |

| Skill Requirement | Moderate manual skill | Machine operator skill; some types (e.g., forming taps) require high skill if used manually |

| Flexibility | Highly flexible for on-site or varied tasks | Less flexible; requires suitable machine setup |

| Lubrication Needs | Necessary to improve thread quality and tool life | Necessary to prevent wear and breakage |

| Manual Suitability | Designed for manual use | Generally unsuitable for manual use |

| Pilot Hole Requirements | Must be drilled accurately beforehand | Also requires precise pilot hole drilling |

Hand taps are operated manually with a tap wrench. A typical hand tap set includes a taper tap, an intermediate tap, and a finishing tap, allowing the operator to cut threads gradually in stages. This stepped approach reduces cutting force, lowers the risk of tap breakage, and helps ensure cleaner threads. [3]

Because the process is manual, maintaining accurate alignment with the hole axis is crucial for precision. Hand taps are slower than machine taps but offer excellent flexibility, making them ideal for low-volume production, repairs, and fieldwork. They perform best on machinable materials and require proper lubrication to improve thread quality and extend tool life.

Machine taps, on the other hand, are designed for use with powered tapping machines, CNC equipment, or stationary drilling machines. They cut threads in a single operation, providing much higher speed and efficiency for medium- to high-volume production. Due to the higher cutting forces and speeds involved, machine taps require rigid and accurate guidance to avoid breakage. They are available in multiple designs suited for different materials, hole types, and thread profiles.

Unlike hand taps, machine taps are generally not suitable for manual operation and tend to be more fragile. Some types such as forming taps can be used manually, but they require greater skill and control. [3]

Ultimately, choosing between hand taps and machine taps depends on factors such as production volume, material characteristics, and available equipment. Regardless of the method, proper preparation, especially correct pilot hole size and adequate lubrication are essential for producing high-quality internal threads.

Premium Quality Cutting Tools at Competitive Prices

Our cutting tools are expertly manufactured and rigorously tested to enhance machining performance and operational savings.

What Are Their Similarities?

Despite their differences, hand taps and machine taps share several important similarities: [1]

- Thread Formation: Both methods aim to create internal threads in a pre-drilled hole so they can properly engage with screws, bolts, and fasteners

- Pre-Drilled Hole Requirement: Both processes begin with drilling a hole to the correct diameter according to the thread type and the tap or threading tool used

- Lubrication: Both benefit from the use of cutting fluids or lubricants to reduce friction, control heat buildup, and produce smoother, higher-quality threads

- Thread Profile: Both techniques produce the same required thread profiles, such as metric or imperial, to ensure compatibility with the intended fasteners

- Tool Selection: Both require specialized tools for cutting threads: hand taps for manual operations and cutting tools or thread mills for machine tapping. Despite differences in tool type, the purpose remains the same

- Thread Depth and Length Control: In both methods, operators must control thread depth and length to achieve proper engagement and functional accuracy

- Accuracy and Quality Inspection: Both processes use inspection tools like thread gauges or calipers to verify pitch diameter, overall diameter, and tolerances of the finished threads

When to Choose Machine Tapping Over Hand Tapping

1. Production Volume Considerations

Choose Machine Tapping When:

- High volumes of identical threads are needed

- Production efficiency is a priority

- Consistent thread quality across multiple parts is required

- Labor costs for manual tapping would be prohibitive

Choose Hand Tapping When:

- Only a few threads are needed

- Each threading operation is unique or custom

- Setup time for machine tapping would exceed the time saved

2. Material Considerations

Choose Machine Tapping When:

- Working with materials of consistent hardness

- Threading materials with good machinability like mild steel, aluminum, or brass

- High-temperature alloys require the precise control of cutting parameters

Choose Hand Tapping When:

- Working with very hard materials where “feel” helps prevent tap breakage

- Material properties vary across the workpiece

- Exotic materials require careful threading approach

3. Hole Configuration Considerations

Choose Machine Tapping When:

- Threading through holes where spiral point taps can push chips forward

- Many holes of identical size need threading

- Holes are in an orientation that’s easy to access with a machine

Choose Hand Tapping When:

- Holes are in difficult-to-access locations

- Hole alignment issues might cause tap breakage in a rigid machine setup

4. Equipment Availability Considerations

Choose Machine Tapping When:

- Appropriate power tools or CNC equipment is readily available

- Proper tap holders and fixtures are on hand

- Production schedule justifies the use of dedicated equipment

Choose Hand Tapping When:

- Working in field conditions with limited equipment

- Power is unavailable or unreliable

- Precision hand tools are the only option available

5. Precision and Control Considerations

Choose Machine Tapping When:

- Consistent depth control is critical

- Thread pitch diameter must be tightly controlled

- Thread positioning relative to other features is critical

Choose Hand Tapping When:

- Operator “feel” is needed to detect problems

- Delicate materials require careful force application

- Correcting alignment issues during tapping may be necessary

Tap Selection Guide

For Hand Tapping Applications:

- Use taper taps for starting threads, especially in difficult materials

- Choose plug taps for general-purpose work and through holes

- Select bottoming taps only for completing threads at the bottom of blind holes

- Consider using thread-forming taps for softer materials like aluminum and copper

For Machine Tapping Applications:

- Use spiral point taps for through holes in most materials

- Choose spiral flute taps for blind holes to ensure chip evacuation

- Select forming taps for materials where thread strength is critical

- Consider TiN or other coatings for high-volume application

Explore our complete selection of hand taps and machine taps to find the right tooling for your application.

Conclusion

The distinction between hand taps and machine taps is more about design optimization than strict categorization of use. As manufacturing technology has evolved, the legacy terminology has remained while the functional differences have become more nuanced.

Both hand taps and machine taps can produce high-quality threads when used appropriately. The key to successful threading lies not in rigidly adhering to traditional nomenclature, but in understanding the design features that make each tap type suitable for specific applications.

For metalworking professionals, the choice between hand and machine tapping should be guided by practical considerations including material properties, hole configuration, production requirements, and available equipment. By considering these factors and following proper threading techniques, machinists can achieve consistent, high-quality threads regardless of whether they choose to tap by hand or machine.

Acquire Premium Quality Cutting Tools at Exceptional Prices with Kota Cutting Tools

Our cutting tools are expertly manufactured and rigorously tested by our technical team to enhance your machining performance and take your business to new heights.

FAQ

Can machine taps be used by hand?

Yes, machine taps can be used by hand, though their design features are optimized for machine operation. When used manually, machine taps may require more force to start and might not provide the same feel as traditional hand taps.

Can hand taps be used in machines?

Yes, hand taps can be used in machines, particularly at lower speeds. However, they may not evacuate chips as efficiently as dedicated machine taps, potentially leading to tap breakage if proper pecking cycles are not employed.

Why does my tap keep breaking?

Tap breakage can occur due to several factors: incorrect hole size, misalignment, insufficient lubrication, inappropriate speed or feed rate, poor chip evacuation, or using the wrong tap type for the material or application.

Can I sharpen a dull tap?

While it is technically possible to sharpen taps using specialized equipment, it’s generally not recommended for precision work. The complex geometry of taps makes proper resharpening difficult without specialized knowledge and equipment.

References

[1] Hand Tapping Vs. Machining Thread: How To Choose Between [Internet]. Premium Parts. 2024. Available from: https://www.premiumparts.com/blog/hand-tapping-vs-machining-thread-how-to-choose-between

[2] Hand Taps vs. Machine Taps: Threading Tools in Detail [Internet]. BAER Tools. 2025. Available from: https://baer.tools/en/blog/hand-taps-vs.-machine-taps-threading-tools-in-detail

[3] Difference: hand taps & machine taps [Internet]. BAER Tools. 2023. Available from: https://baer.tools/en/blog/difference-hand-taps-machine-taps

[4] Hand Taps: A Comprehensive Guide | All You Need To Know [Internet]. Slugger Threading tools. 2024. Available from: https://www.sluggertool.com/hand-taps