KCT HSS MTS Countersinks

KCT HSS MTS Countersinks

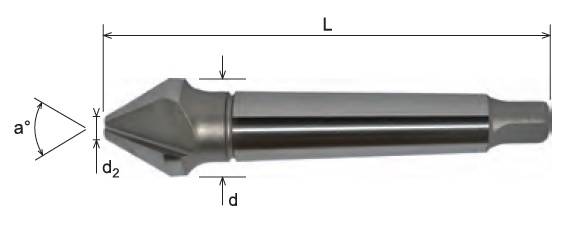

60º DIN 334D

| d | Morse Taper |

d 2 | L |

| 31.5 | 2 | 10 | 118 |

| 40 | 3 | 12.5 | 150 |

| 50 | 3 | 16 | 160 |

| 63 | 4 | 20 | 180 |

| 80 | 4 | 25 | 190 |

KCT HSS MTS Countersinks

90º DIN 335D

| d | Morse Taper |

d 2 | L |

| 31.5 | 2 | 4.2 | 112 |

| 40 | 3 | 10 | 140 |

| 50 | 3 | 14 | 150 |

| 63 | 4 | 16 | 180 |

| 80 | 4 | 22 | 190 |

Countersinking is done to insure that flat head screws sit flush to the work piece. A countersink produces a conical hole matching the angle of the screw so that when the screw is fully engaged the head will sit flush or slightly below the surface. Countersinks have a greater range of applications and angles. Standard sizes include 60°, 90° as well as less popular 82°, 100°,110⁰ and 120° included angles. Because of the angle on this shank driven rotary tool they can be used to remove burrs or chamfer the corner of a part. Single and multiple flute countersinks are used to chamfer threaded holes or provide a good seat for counter sunk fastener. There are also tools designed to chamfer or face the back side of a drilled or tapped hole

In addition to the standard cylindrical shank, the Morse taper bit shank (MTS) is also available for wide variety of machines.

Get most jobs done with KCT HSS countersinks. Choose from an extensive array of countersinks for different types of materials such as Steel, Stainless steel, Aluminium, Etc..