KCT HSS-CO8 TICN 4 FLUTE END MILLS - REGULAR

KCT HSS-CO8 TICN 4 FLUTE END MILLS

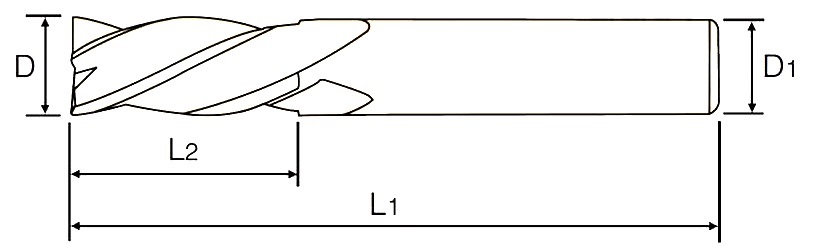

| d mm | d1 mm | L2 | L1 |

| 1 | 6 | 4 | 55 |

| 1.5 | 6 | 4 | 55 |

| 2 | 6 | 6 | 55 |

| 2.5 | 6 | 7 | 55 |

| 3 | 6 | 10 | 55 |

| 3.5 | 6 | 12 | 60 |

| 4 | 6 | 12 | 55 |

| 4.5 | 6 | 15 | 65 |

| 5 | 6 | 15 | 65 |

| 5.5 | 6 | 15 | 65 |

| 6 | 6 | 15 | 60 |

| 6.5 | 8 | 15 | 65 |

| 7 | 8 | 20 | 70 |

| 7.5 | 8 | 20 | 70 |

| 8 | 8 | 20 | 75 |

| 8.5 | 10 | 20 | 75 |

| 9 | 10 | 25 | 80 |

| 9.5 | 10 | 25 | 80 |

| 10 | 10 | 25 | 80 |

| 10.5 | 12 | 30 | 90 |

| 11 | 12 | 30 | 90 |

| 11.5 | 12 | 30 | 90 |

| 12 | 12 | 30 | 90 |

| 13 | 12 | 35 | 95 |

| 14 | 16 | 35 | 100 |

| 15 | 16 | 40 | 105 |

| 16 | 16 | 40 | 105 |

| 17 | 16 | 40 | 105 |

| 18 | 16 | 40 | 105 |

| 19 | 20 | 45 | 115 |

| 20 | 20 | 45 | 115 |

| 21 | 20 | 45 | 115 |

| 22 | 20 | 45 | 115 |

| 23 | 20 | 50 | 125 |

| 24 | 20 | 50 | 125 |

| 25 | 20 | 50 | 125 |

| 26 | 25 | 50 | 125 |

| 27 | 25 | 50 | 125 |

| 28 | 25 | 50 | 125 |

| 29 | 25 | 50 | 125 |

| 30 | 25 | 50 | 125 |

| 31 | 32 | 60 | 145 |

| 32 | 32 | 60 | 145 |

| 33 | 32 | 60 | 145 |

| 34 | 32 | 60 | 145 |

| 35 | 32 | 60 | 145 |

| 36 | 32 | 65 | 150 |

| 37 | 32 | 65 | 150 |

| 38 | 32 | 65 | 150 |

| 39 | 32 | 65 | 150 |

| 40 | 32 | 65 | 150 |

| 42 | 42 | 70 | 160 |

| 45 | 42 | 70 | 160 |

| 48 | 42 | 75 | 165 |

| 50 | 42 | 75 | 165 |

KCT HSS-CO8 End mills are made from premium German Raw Material. Cobalt 8% Provides better wear resistance, higher hot hardness and toughness than high speed steel (HSS) end mills. There is very little chipping or microchipping under severe cutting conditions, allowing the tool to run 10% faster than HSS, resulting in excellent metal removal rates and good finishes. KCT HSS-CO8 End mills is a cost-effective solution. TICN coating simultaneously provides higher hardness and can show a slightly lower friction coefficient in many applications. It is primarily used to achieve enhanced abrasive wear resistance.

- 8% Cobalt, fully CNC precision ground

- Available in 2 Flute & 4 Flute

- All centre cutting, bright or TICN coated

- High quality- low cost tooling

- For machining carbon steel, alloy steels, tool steels, aluminium and aluminium alloys

- Materials up to HRc35