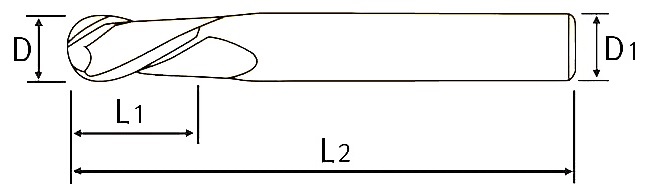

KCT SOLID CARBIDE 2 FLUTE BALL NOSE END MILL

KCT SOLID CARBIDE 2 FLUTE BALL NOSE END MILL

| d mm | d1 mm | L2 | L1 |

| 0.2 | 4 | 0.4 | 50 |

| 0.3 | 4 | 0.6 | 50 |

| 0.4 | 4 | 0.8 | 50 |

| 0.5 | 4 | 1 | 50 |

| 0.6 | 4 | 1.2 | 50 |

| 0.8 | 4 | 1.6 | 50 |

| 1 | 6 | 3 | 50 |

| 1.5 | 4 | 4 | 50 |

| 2 | 6 | 6 | 50 |

| 3 | 6 | 8 | 60 |

| 4 | 6 | 11 | 70 |

| 5 | 6 | 13 | 80 |

| 6 | 6 | 13 | 80 |

| 7 | 8 | 16 | 90 |

| 8 | 8 | 19 | 90 |

| 9 | 10 | 19 | 100 |

| 10 | 10 | 22 | 100 |

| 12 | 12 | 26 | 110 |

| 14 | 14 | 26 | 120 |

| 16 | 16 | 30 | 130 |

| 18 | 18 | 35 | 102 |

| 20 | 20 | 38 | 130 |

KCT Solid Carbide Ball Nose End Mills are an efficient solution for machinists who need a tool to work with different materials and different types of cut. KCT solid carbide end mills offer cost efficiency and flexibility while maintaining high Metal Removal Rates.

Solid carbide end mills provides better rigidity than high-speed steel (HSS). It is extremely heat resistant and used for high speed applications. Solid Carbide end mills provide better rigidity and can be run 2-3X faster than HSS on CNC.

KCT Solid Carbide Ball Nose End mills featuring a full radius, are ideally suited for milling 3-D contoured parts. The full radius, or ball shape, permits good accuracy contouring and profiling

- Micro Grain Carbide, fully CNC precision ground

- All centre cutting, TIALN coated

- Good quality- low cost tooling

- For machining carbon steel, alloy steels, stainless steel, pre-hardened steel & hardened steel

- Materials up to HRc55