SOMTA HSS MTS Counterbores

SOMTA HSS MTS Counterbores

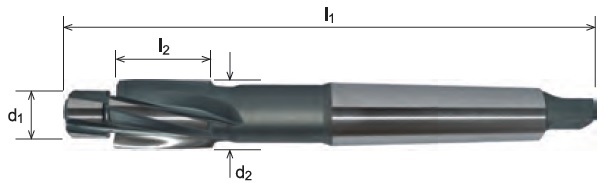

| To Suit Capscrew | d 2 | d1 | l2 | Morse Taper | l2 |

| M14 | 24 | 16 | 30 | 2 | 150 |

| M16 | 26 | 28 | 35 | 3 | 180 |

| M18 | 30 | 20 | 35 | 3 | 180 |

| M20 | 33 | 22 | 40 | 3 | 190 |

| M22 | 36 | 24 | 40 | 3 | 190 |

| M24 | 40 | 26 | 40 | 3 | 190 |

A counterbore is used to enlarge the opening of a hole producing a flat bottom so a socket-head screw will fit flush with the surface of the part. Lock washers may be used to ensure a secure assembly. Typically counterbores are used for a single purpose

SOMTA Counterbores are made with standard dimensions for a certain size of screw and also can be produced in sizes that are not related to any particular screw size. In either case, the tip of the counterbore has a reduced diameter section referred to as the pilot, a feature essential to assuring concentricity between the counterbore and the hole being counterbored. Counterbores matched to specific screw sizes generally have integral pilots that fit the clearance hole diameter associated with a particular screw size

SOMTA MTS counterbore produced with Morse taper shank. SOMTA Counterbores also comes with parallel shank which is designed to fit into a drill chuck.