V-Coil HSSG STI Taps - M (Second Lead)

V-Coil STI-Taps – M (Second Lead)

for Wire-Thread-Inserts ISO 2 (6H)

Form D HSS-G Tolerance ISO1 (4H)

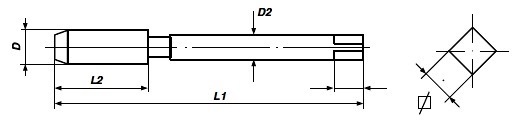

| Nominal Diameter, D (mm) |

B | L 1 | L 2 | D 2 | ▢ |

| M 2 x 0.4 | 2.5 | 44.5 | 9.5 | 2.8 | 2.24 |

| M 2.5 x 0.45 | 3.1 | 48 | 11 | 3.15 | 2.5 |

| M 3 x 0.5 | 3.6 | 53 | 13 | 4 | 3.15 |

| M 3.5 x 0.6 | 4.3 | 53 | 13 | 4.5 | 3.55 |

| M 4 x 0.7 | 4.9 | 58 | 16 | 5 | 4 |

| M 5 x 0.8 | 6 | 66 | 19 | 6.3 | 5 |

| M 6 x 1.0 | 7.3 | 72 | 22 | 8 | 6.3 |

| M 7 x 1.0 | 8.3 | 72 | 22 | 9 | 7.1 |

| M 8 x 1.25 | 9.6 | 80 | 24 | 10 | 8 |

| M 8 x 1.0 | 9.3 | 80 | 24 | 10 | 8 |

| M 9 x 1.25 | 10.6 | 85 | 25 | 8 | 6.3 |

| M 10 x 1.5 | 11.9 | 89 | 29 | 9 | 7.1 |

| M 10 x 1.25 | 11.6 | 85 | 25 | 8 | 6.3 |

| M 10 x 1.0 | 11.3 | 85 | 25 | 8 | 6.3 |

| M 11 x 1.5 | 12.9 | 89 | 29 | 9 | 7.1 |

| M 12 x 1.75 | 14.3 | 95 | 30 | 11.2 | 9 |

| M 12 x 1.5 | 14 | 95 | 30 | 11.2 | 9 |

| M 12 x 1.25 | 13.6 | 95 | 30 | 11.2 | 9 |

| M 12 x 1.0 | 13.3 | 95 | 30 | 11.2 | 9 |

| M 14 x 2.0 | 16.6 | 102 | 32 | 12.5 | 10 |

| M 14 x 1.5 | 16 | 102 | 32 | 12.5 | 10 |

| M 14 x 1.25 | 15.6 | 102 | 32 | 12.5 | 10 |

| M 14 x 1.0 | 15.3 | 102 | 32 | 12.5 | 10 |

| M 16 x 2.0 | 18.6 | 112 | 37 | 14 | 11.2 |

| M 16 x 1.5 | 18 | 104 | 29 | 14 | 11.2 |

| M 18 x 2.5 | 21.3 | 118 | 38 | 16 | 12.5 |

| M 18 x 2.0 | 20.6 | 104 | 29 | 14 | 11.2 |

| M 18 x 1.0 | 20 | 104 | 29 | 14 | 11.2 |

| M 20 x 2.5 | 23.3 | 118 | 38 | 16 | 12.5 |

| M 20 x 2.0 | 22.6 | 113 | 33 | 16 | 12.5 |

| M 20 x 1.5 | 22 | 113 | 33 | 16 | 12.5 |

| M 22 x 2.5 | 25.3 | 130 | 45 | 18 | 14 |

| M 22 x 2.0 | 24.6 | 120 | 35 | 18 | 14 |

| M 22 x 1.5 | 24 | 120 | 35 | 18 | 14 |

| M 24 x 3.0 | 27.9 | 138 | 48 | 20 | 16 |

| M 24 x 2.0 | 26.6 | 127 | 37 | 20 | 16 |

| M 24 x 1.5 | 26 | 120 | 35 | 18 | 14 |

V-COIL Thread repair insert system

In the mechanical engineering and automotive sector, damaged threads such as spark plugs, bolts, oil drain screw threads, oxygen sensor or exhaust mounts lead to costly and time-intensive replacements.

For parts with damaged or defective threads, V-COIL Thread Insert System can provide a second chance.

Worn and damaged threads can be replaced by threading inserts in just four steps. They are stronger and with the same nominal diameter as before

- V-COIL offers many practical thread repair sets for the following thread types: Metric, metric fine, UNC, UNF, UNx8 as well as for BSW Whitworth and G (BSP) pipe threads.

- V-COIL Tools for repairing threads are packed in quality, sturdy packaging

- V-COIL STI-taps, inserting tools as well as the wire thread inserts can be purchased separately

- V-COIL thread repair sets include wire thread inserts 1.5xD length. Wire thread inserts in the refill packs are available in 1.0xD to 3.0xD lengths.