Revolving Centers

Choosing the right revolving center is critical as it is the driving force while turning. At Kota Cutting Tools, we offer a variety of revolving centers featuring circular serrated edges and spring-loaded center points, designed to prevent splitting under pressure. We guarantee all revolving centers to run straight and true for optimal performance.

What Is Revolving Center

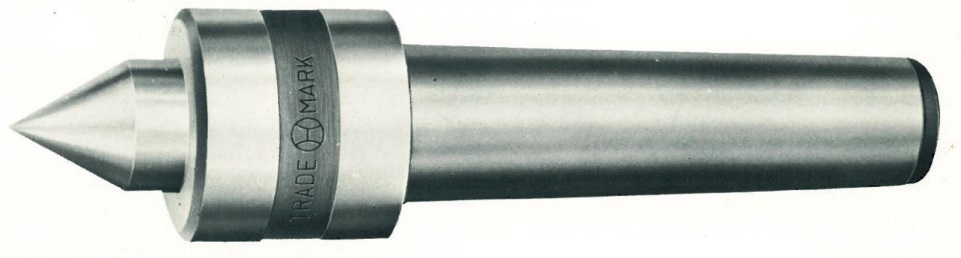

A revolving center, also known as a live center is a tool used in lathe machines. It is positioned at the non-driven or tailstock end and is designed to rotate with the workpiece. Constructed with a 60° cone and supported by precision bearings, the revolving center reduces friction between the center and the workpiece. This reduces heat generation, ensuring smoother operations and extended tool life.

Our Selection of Revolving Centers

A wide selection of cutting tools catering to the diverse needs of industries in Malaysia. Whatever your application, we have the perfect tool for you.

Choosing the Right Cutting Tools

Not sure which tool suits your application? Talk to our technical team today or request a quote for the perfect cutting tools for your application.

FAQ

What is a revolving center for a lathe?

A revolving center, or live center, is a lathe accessory used at the tailstock end to support the workpiece during machining. It rotates at high speed along with the workpiece, reducing friction and heat without requiring separate lubrication.

Can I use a revolving center for support during tapping or threading operations?

Absolutely. When using machine taps for threading, especially on longer or slender parts, a revolving center helps stabilize the workpiece. This improves thread alignment and prevents tap breakage, which is crucial for high-accuracy threading tasks.

Should I use a revolving center when machining with slitting saws or end mills?

While slitting saws and end mills are primarily used on milling machines, if you’re turning a part that requires side milling or slotting in a lathe setup, a revolving center can help support the workpiece. This ensures stability and better surface finish during secondary operations.

What is the difference between a revolving center and a dead center?

A revolving center rotates with the workpiece and is supported by precision bearings, which reduces friction and wear. A dead center, on the other hand, remains stationary and is typically used for initial setup or light machining tasks.

How to use a revolving center in the lathe?

Insert the revolving center into the tailstock, align it with the workpiece, and apply light pressure. Ensure proper alignment for smooth and efficient turning.

Are the revolving center and live center the same?

Yes. The revolving center is also known as a live center. Both terms refer to the same tool used in lathe machining.

What types of revolving centers do you provide?

We offer a range of revolving centers, including PointTech GG Revolving Center, PointTech GG CNC High-Speed Revolving Center, IIDA High-Speed Revolving Center, and IIDA CNC High-Speed Revolving Center.

How to extend the tool life of revolving centerl?

To extend the tool life of a revolving center:

- Choose a suitable revolving center for the material and specific machining application

- Consider the workpiece weight and machining speed to maintain precision

- Clean the revolving center regularly and apply proper lubrication to ensure steady and long-lasting performance