A Complete Overview of the Best Thread Taps for Machinists and DIY Enthusiasts

The word ‘threading’ might conjure images of needles and thread in everyday contexts but within the manufacturing industry, it signifies a far more robust process.

From everyday household screws and bolts to sophisticated aerospace assemblies, threads provide secure and often reversible connections that are critical to functionality.

To allow these tools to hold together nicely and snugly, selecting the optimal tap is one of the most critical steps in ensuring the integrity and longevity of the final product.

Now that you’ve found this guide, let us help you understand threading taps better whether you’re a seasoned manufacturing professional or DIY enthusiast.

Basic Types of Threading Taps

The foundation of successful thread creation lies in selecting the appropriate tap type and understanding its functions to best fit your project requirements.

Let’s begin by exploring the main categories:

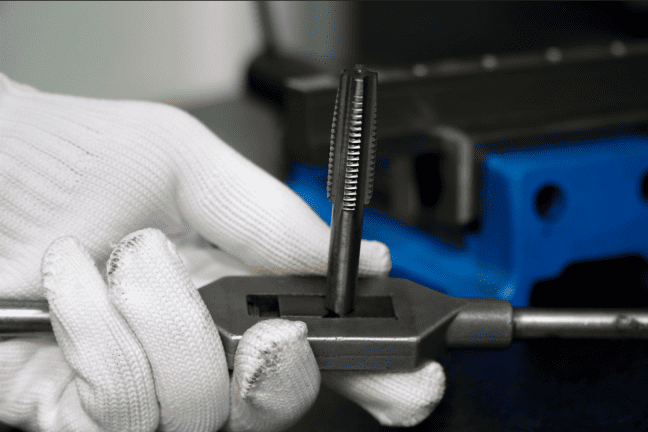

1. Hand Taps

Hand taps are the most basic type of threading tap and are readily available in most hardware stores. As their name suggests, hand taps are operated manually to create internal threads and are generally not used for CNC machining.

For individuals new to threading or those undertaking small-scale projects, hand taps offer a cost-effective way to learn the process without the need for significant investment in machinery.

They are particularly versatile for situations where a fully equipped workshop is unavailable and only a limited number of threads are required [1].

Furthermore, their manual operation provides considerable flexibility, allowing them to be used in confined or unconventional locations where power tools may not be practical.

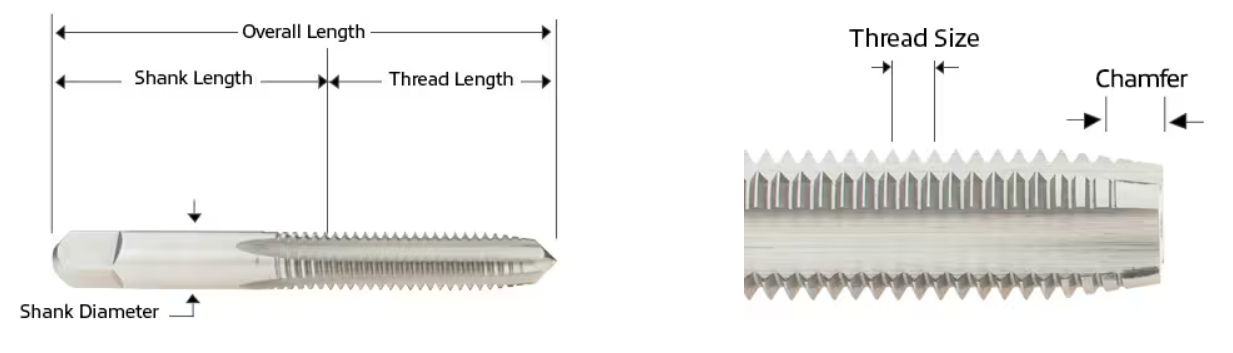

These tools are normally sold in sets of three as they’re distinguished from one another by the

length of cutting chamfer:

| Hand Tap Types | Features / Uses |

| Taper Taps |

|

Plug Taps (Intermediate Taps) |

|

Bottoming Taps (Finishing Taps) |

|

2. Machine Taps

In industrial manufacturing, the time efficiency of automated processes makes machine tapping the go-to method.

Unlike hand taps, which often require multiple passes, machine taps are designed for single-operation thread creation for their use in power-driven machines like drill presses, lathes, and CNC machining centers.

They are typically more robust than hand taps and are designed for higher cutting speeds and feed rates.

Here are some examples of machine tap types you could choose from for CNC applications:

| Machine Tap Types | Features / Uses |

| Spiral Point Taps

|

|

| Spiral Flute Taps / Helical Flute Taps

|

|

Threading dies are specialized cutting tools essential in manufacturing for creating external screw threads on cylindrical components such as bolts, screws, and rods.

These tools, equipped with hardened cutting edges and flutes for efficient chip evacuation, come in both fixed and adjustable designs, the latter allowing for precise thread size adjustments.

Although they are primarily used manually with a die stock for tasks ranging from thread repair (rethreading) to custom fastener creation, threading dies can also be employed with powered threading machines for increased efficiency, particularly with larger workpieces or higher production volumes [2].

4. Forming Taps (Roll Forming Taps)

Cutting taps create threads by systematically removing material to establish the threaded profile that will interlock with a fastener’s external threads.

In contrast, forming taps, also known as roll forming or fluteless taps, operate without material removal.

Instead, they employ lobes to cold-form threads by displacing the material within the pre-drilled hole, and pressing it into the desired thread shape. This chipless process yields strong, precise, and burr-free inter

Material Considerations

Choosing the correct tap material, tailored to the specific workpiece material, lays the groundwork for a smoother threading process.

This upfront effort in proper tool selection significantly reduces your workload, saves valuable time during machining, and ultimately leads to greater productivity by ensuring efficient cutting and prolonging the life of your taps.

- High-Speed Steel (HSS)

High-speed steel (HSS), a time-tested material in cutting tool technology for over a century, remains a cost-effective and adaptable choice for general threading of softer steels, aluminum, and plastics.

There are various HSS grades in the market, such as M2, M35, and M42, that provide different degrees of hardness and resistance to wear, allowing for tailored performance [3].

To meet the unique requirements of diverse job specifications, custom taps can be manufactured with a wide array of specialized features. These features include straight flute taps, spiral point taps, and spiral flute taps.

- Cobalt High-Speed Steel (HSSE)

Cobalt High-Speed Steel (HSSE) represents an upgrade from standard HSS through the addition of cobalt (typically 5-8%).

This alloying element significantly enhances the material’s properties, resulting in increased hardness, improved resistance, and enhanced wear resistance.

These characteristics make HSSE taps ideal for threading more challenging materials like harder steels, stainless steels, and certain grades of cast iron.

While HSSE taps offer superior performance on tougher materials, they typically come at a higher cost than standard HSS taps.

- Carbide

Carbide taps represent the pinnacle of hardness and wear resistance in tap materials as they are manufactured from extremely hard composite materials consisting of tungsten carbide particles bonded together by a metallic binder (usually cobalt).

Their exceptional properties make them the preferred choice for demanding applications in high-speed tapping and threading hard materials that would rapidly wear our HSS and HSE.

However, carbide taps tend to be more brittle and less tolerant to interrupted cuts, vibrations, or misalignment which makes proper machine setup and rigid workholding crucial [4].

1. Tapping in Exotic Alloys and Composite Materials

Tapping titanium and other exotic alloys presents significant challenges due to their inherent properties designed for extreme environments.

Unlike conventional materials, their machining characteristics demand careful consideration as they exhibit high strength and toughness which can lead to accelerated tool wear and breakage.

Let’s have a look at the two most common types of exotic materials and their considerations:

- Titanium:

- High positive rake angles can promote a shearing action instead of tearing, which is essential for chip formation and surface finish.

- Coatings like TiAlN or AlCrN are recommended to improve wear resistance and reduce friction.

- Coolant is essential for dissipating heat as titanium has poor thermal conductivity.

- Higher feed rates are often preferred to promote chip thinning and reduce the time the cutting edge is in contact with the workpiece.

- Inconel:

- Known for its extreme hardness and notch sensitivity.

- Taps made from premium HSSE or carbide with robust designs and sharp cutting edges are necessary.

- Through-coolant is highly beneficial for chip evacuation and temperature control.

- Very low cutting speeds and high torque are typical.

Therefore, proper tooling and planning when exploring tapping in exotic alloys is important to ensure maximum efficiency.

Premium Quality Cutting Tools at Competitive Prices

Our cutting tools are expertly manufactured and rigorously tested to enhance machining performance and operational savings.

Application-Specific Advice

Choosing the right tap isn’t a one-size-fits-all endeavor. The characteristics of the hole you’re creating – whether it passes all the way through or stops short – significantly influence the optimal tap design.

Similarly, challenging hole geometries demand specialized tap features and tapping techniques.

Let’s explore the key considerations for each of these scenarios:

1. Choosing Taps for Through Holes vs. Blind Holes

- For through Holes

Spiral point taps are generally the most efficient choice due to their ability to push chips ahead. They feature angled flutes at the point that effectively push chips forward, ahead of the cutting action.

This prevents chip clogging within the flutes, leading to faster tapping cycles, reduced torque requirements, improved thread quality, and lower risk of tap breakage.

Other than spiral point taps, straight flute taps can also be used with proper chip evacuation.

- Blind Holes

Spiral flute taps are preferred for pulling chips back out of the hole.

On the other hand, forming taps can also be excellent for blind holes in suitable materials (e.g. aluminium, copper, and some softer steels) as they produce no chips.

2. Tapping in Challenging Geometries

When faced with intricate curves and unconventional forms of organic geometries, machinists have a wealth of techniques at their disposal to achieve precise and reliable tapped threads.

Mastering these specialized methods unlocks the potential to create functional features even in the most demanding designs.

- Interrupted Thread Tapping

Instead of continuous cutting, interrupted thread tapping employs specialized taps with deliberate gaps in their cutting edges. This ingenious design transforms the threading process into a series of short, impactful cuts, leaving behind segmented threads.

It is particularly useful when machining high-strength alloys like those frequently encountered in aerospace and automotive manufacturing.

- Peck Tapping

To combat excessive heat and the challenge of chip accumulation, especially when threading deep holes or machining demanding materials, the technique of peck tapping is employed.

Instead of a continuous plunge, the tap is advanced into the workpiece in a series of short, controlled movements known as “pecks.”

After each peck, the tap is partially or fully retracted, providing crucial opportunities for chips to break and be expelled from the hole before the next increment of cutting begins.

This technique can be implemented on both sophisticated CNC machining centers and during manual tapping operations.

Industry Standards & Economic Considerations

Adhering to established industry standards in threading operations is not just about compliance but also the assurance of reliability, compatibility, and quality of your threaded components on a global scale.

This includes:

- ISO (International Organization for Standardization): Defines standard thread profiles (e.g., metric threads – M series), tolerances, and gauging systems. Adhering to ISO standards ensures the interchangeability of threaded components globally.

- ANSI (American National Standards Institute): Defines thread standards used primarily in North America (e.g., Unified National Threads – UNC, UNF).

- DIN (Deutsches Institut für Normung): German national standards organization that also defines various thread forms and tap dimensions.

These standards influence tap dimensions, thread forms, and tolerances, ensuring that taps produce threads that meet specific requirements for fit and function. When selecting taps, it’s crucial to ensure they comply with the relevant standards for the intended application.

Tapping in Challenging Geometries

The financial aspect of tap selection goes beyond the initial purchase price. A holistic view considers productivity, tool life, and the overall quality of the finished product.

| Features | Hand Taps | Machine Taps | Forming Taps |

| Upfront cost | Low | High | Moderate to high |

| Productivity | Low | High | Medium to high |

| Accuracy | Low | High | High |

| Specific Benefits | Simple for small jobs/repairs/manual | For machine feeding, faster cycles, better accuracy | No chips (ductile), stronger threads, better finish |

| Potential Drawbacks | Slow, requires skill, lower accuracy, not for production | Higher initial cost | Limited to ductile materials, precise hole size needed |

| Overall Cost-Effectiveness (High Volume) | Lowest | Medium to high | High |

Choosing the cheapest tap might seem like a way to save money initially, but it often leads to higher costs in the long run due to reduced productivity, increased tool consumption, potential quality issues, and more downtime.

Therefore, investing in the right type of tap, considering industry standards and the specific demands of the application, and prioritizing tool life is crucial for achieving cost-effective and high-quality threading operations.

It’s about finding the sweet spot between the initial investment and the overall efficiency and reliability of the threading process.

Spin Your Threading Success Story with Kota Cutting Tools!

Mastering the selection and application of threading taps is an investment in the quality, efficiency, and ultimately, the success of your projects.

With a thorough understanding of a diverse range of taps, considering material compatibility, applying best practices, and staying informed about advanced technologies, you can confidently tackle any threading challenge.

Partner with Kota Cutting Tools to bring your designs to life with unmatched precision and efficiency.

We’re ready to collaborate and provide tailored solutions that meet your exact requirements. Let’s discuss your project – connect with us now!

FAQ

1. What is the difference between tapping and drilling?

Drilling and tapping are distinct processes in manufacturing. Drilling is a material removal process that utilizes a drill bit to create a cylindrical hole in a workpiece.

In contrast, tapping is a process, which can involve material removal or displacement, used to create internal screw threads within a pre-existing hole.

This is achieved using a tool called a tap, which features cutting edges or forming lobes that generate the helical grooves of the thread.

2. What is the strongest type of tap?

The “strength” of a tap can be understood in several ways.

When considering resistance to breakage, solid carbide taps typically exhibit the highest resistance to wear and can withstand significant cutting forces when working with very hard materials.

However, it’s important to note that carbide is also more brittle and can chip under sudden impact. High-speed steel (HSS) taps, particularly those containing cobalt (HSSE), provide a favorable combination of hardness and toughness, making them less likely to break in a wide range of applications.

Alternatively, if “strength” refers to the durability of the threads produced, forming taps, also known as roll forming taps, create the strongest internal threads.

This is because they cold-form the material rather than cutting it, which leads to work hardening and a continuous grain flow within the thread, enhancing its strength.

3. How do I choose a tap for my project?

So, you’re ready to tap some threads? Choosing the right tool is a critical first step. Begin by knowing your material. Is it soft aluminum or tough stainless steel? This will narrow down your tap material options.

Then, examine your hole. Is it all the way through, or does it have a bottom? This will guide your selection of flute type. Absolutely crucial is identifying the exact thread you need – size and type (like M6 or 1/4″-20).

References

[1] Difference: Hand Taps and Machine Taps[Internet] Available from: https://baer.tools/en/blog/difference-hand-taps-machine-taps?srsltid=AfmBOooIhqzlePU_OTj4-puqfMy-jTHuvS-v4tmyQor1y1oMvIj0CJ-Z

[2] Giorleo L, Cartapani M. Influence of Die Threading and Finishing Length in the Thread-Rolling Process Using Flat Dies: A Numerical Analysis. J Inst Eng India Ser C. 2021;103(4). doi:10.1007/s40032-021-00784-7

[3] Liu Y, Li D, Shao Q, Ma H, Kang J, Su R. Study on Friction and Wear Behaviors of M42 High Speed Steel. J Phys Conf Ser [Internet]. 2022 [cited 2025 Apr 20];2168(1):012025. Available from: https://doi.org/10.1088/1742-6596/2168/1/012025.

[4]Threading Tap Materials: Traits and Capabilities. [Internet] Available from: https://www.regalcuttingtools.com/learning-center/articles/threading-tap-materials-traits-and-capabilities

Acquire Premium Quality Cutting Tools at Exceptional Prices with Kota Cutting Tools

Our cutting tools are expertly manufactured and rigorously tested by our technical team to enhance your machining performance and take your business to new heights.