End Mills

End mills are versatile cutting tools used in milling applications. They are essential for creating shapes and holes in various directions, making them ideal for milling, profiling, contouring, slotting, counterboring, drilling, and reaming tasks. Designed with cutting teeth on both the face and edges, end mills can handle diverse materials and machining needs.

At Kota Cutting Tools, our comprehensive range of tools sets new standards for quality and performance. Every end mill is manufactured to meet the narrowest tolerances, ensuring a long tool life and exceptional performance. Our extensive product range is readily available in stock, with short-notice availability for urgent requirements. Additionally, we offer custom-made tools tailored to individual customer needs.

Our Products

A wide selection of cutting tools catering to the diverse needs of industries in Malaysia. Whatever your application, we have the perfect tool for you.

Choosing the Right Cutting Tools

Not sure which tool suits your application? Talk to our technical team today or request a quote for the perfect cutting tools for your application.

Frequently Asked Questions

What are end mills used for?

End mills are used in milling operations to create precise shapes, slots, and holes in materials. They are commonly applied in profiling, contouring, drilling, reaming, chamfering, roughing, and finishing tasks.

What types of end mills do Kota Cutting Tools offer?

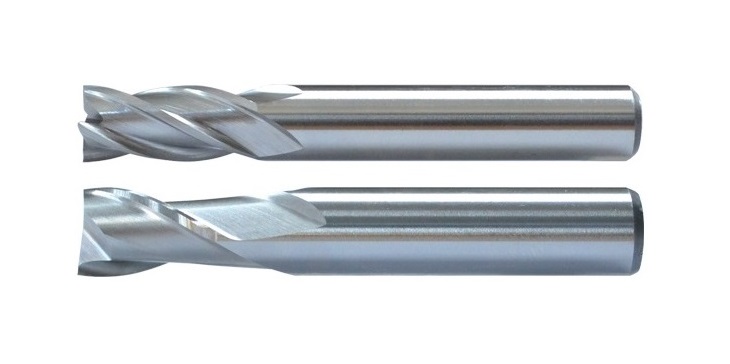

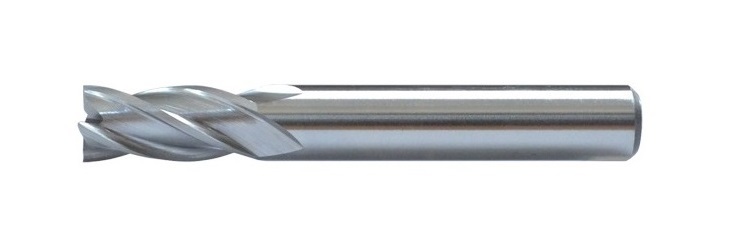

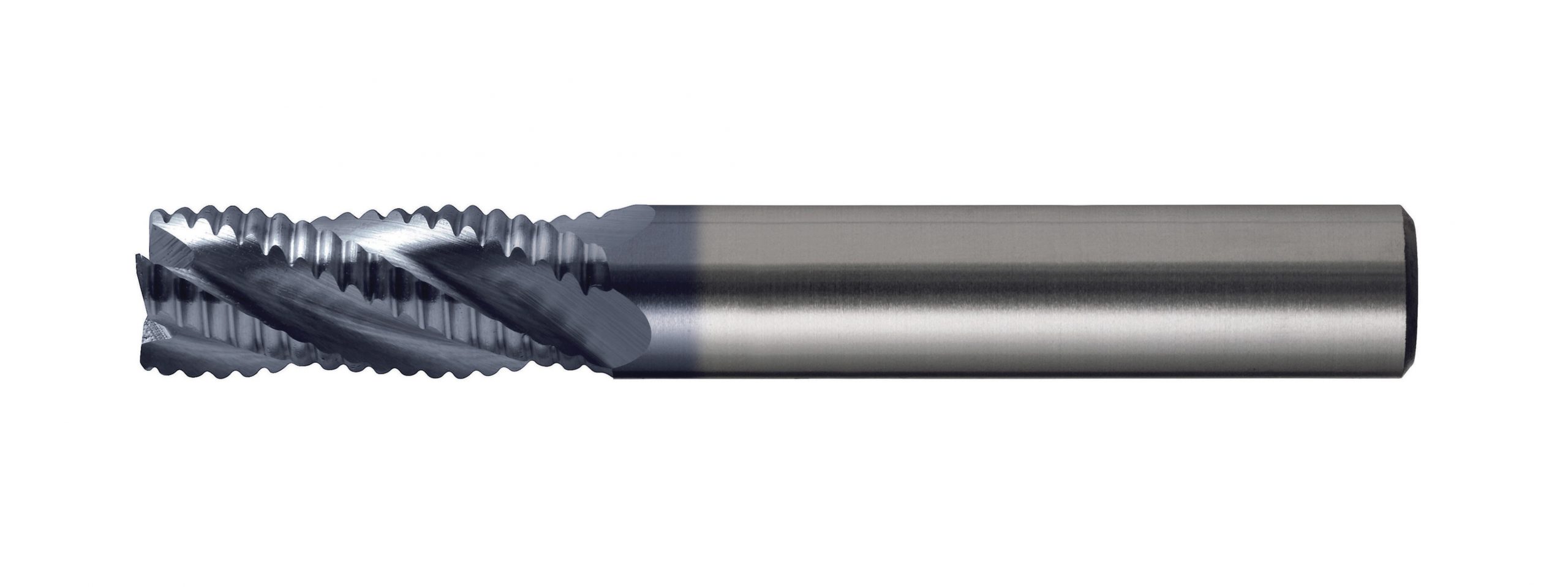

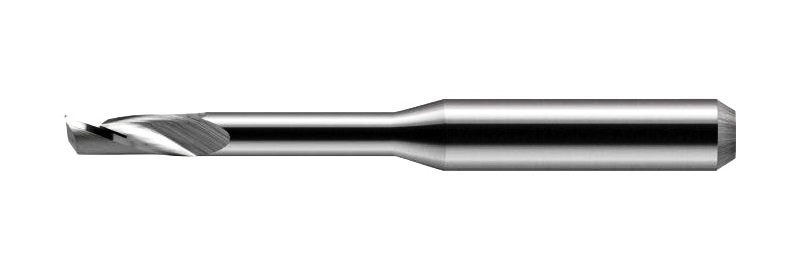

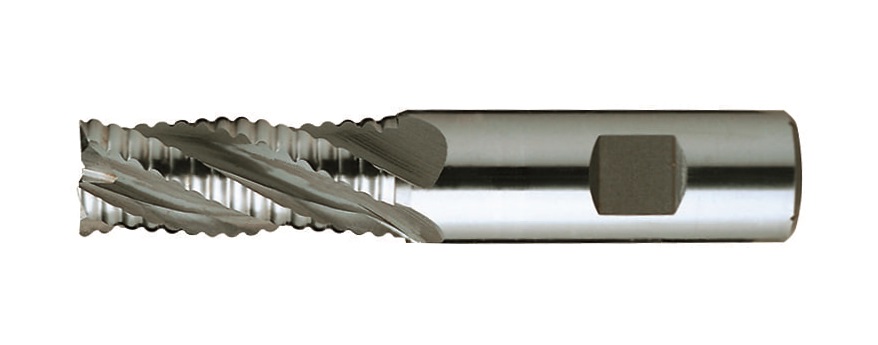

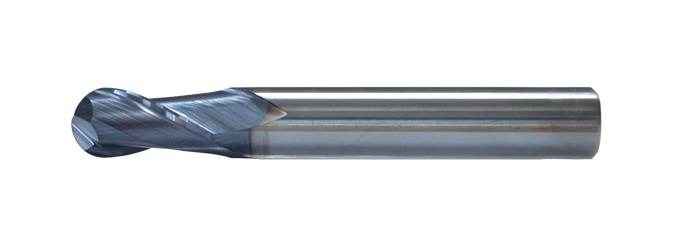

We offer ball nose end mills and roughing end mills, available in various flute designs to suit different machining needs.

What flute types of end mills do you have?

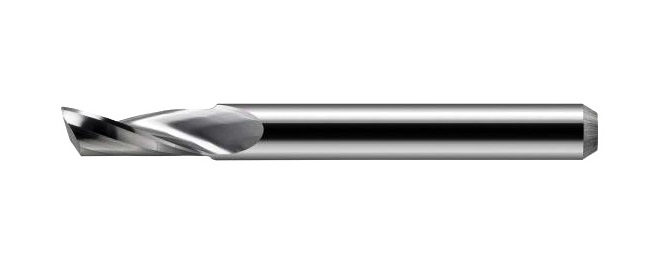

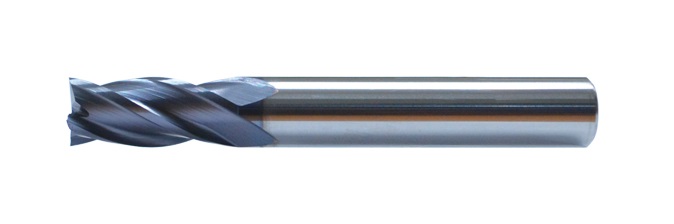

Our end mills come in various flute configurations, including:

- 2-flute for soft materials like aluminum

- 4-flute for harder materials requiring higher precision

- Multi-flute for high-speed machining and finishing

What are the materials of end mills made of?

Our end mills are manufactured using premium materials such as carbide and HSS (High-Speed Steel). These materials ensure strength, durability, and excellent performance in machining applications.

Which end mills are suitable for me?

The right end mill depends on your material, machining operation, and desired finish. Contact our technical team to get expert guidance on selecting the most suitable end mill for your specific needs.

How do I maintain my end mills for extended life?

Proper maintenance includes regular cleaning, ensuring correct tool storage, and using appropriate cutting speeds and feeds. Inspect tools for wear and replace them as necessary to maintain optimal performance.

Do you offer custom end mill solutions?

Yes, we provide customized end mills tailored to unique applications and requirements. Reach out to our team to discuss your specific needs.