The Function of a Reamer: A Comprehensive Guide for Machinists

In the machinery industry, precision is the ultimate standard where every cut and finish hinges on the tools you use, and the difference between success and failure often comes down to the choices you make.

One often-overlooked yet indispensable tool in the machining world is the reamer.

Far from being just another cutting instrument, reamers are key to achieving precision finishes and maintaining exact tolerances, ensuring that every micron matters.

But what exactly is a reamer, and why is it so indispensable to machinists?

Get ready to sharpen your knowledge and discover how this humble tool can make a difference in your projects in this article.

What are Reamers Used For?

Reamers are rotary tools with one or more teeth, used to remove a thin layer of metal from the surface of a machined hole. These rotary finishing tools are used for adding a desired finish to the inside of predrilled holes.

These rotary finishing tools are essential in applications where accuracy is mandatory, such as in aerospace, automotive, and manufacturing industries.

Their function is to ensure that the type of drilled holes are perfectly shaped, properly sized, and have a high-quality surface finish, making them vital for creating precise fits for bolts, pins, and other components [1].

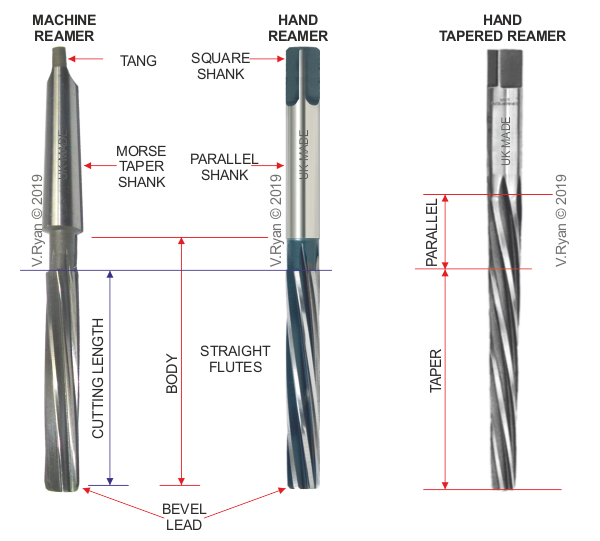

Components of a reamer often consist of:

- Axis: The reamer’s backbone is a central axis which is an important geometric feature that characterizes motion errors.

- Body: This portion is the main section that carries the cutting flutes and performs the reaming operation.

- Back Taper: The back taper is a slight reduction in diameter from the cutting end to the shank. It helps to reduce friction and prevent the reamer from binding in the hole.

- Bevel Lead: The bevel lead is the tapered front section of a reamer’s cutting edge, designed to guide the tool smoothly into the hole, reduce initial cutting force, and prevent misalignment or damage.

- Flutes: Flutes are the grooves or channels that help to remove chips and debris from the hole during the reaming process. The number of flutes can vary, with more flutes generally providing a smoother finish.

Types of Reamers

Although reamers may look alike, each type is specially designed to perform best in particular applications.

Therefore, recognizing the unique features of each type is key to maximizing efficiency and achieving the best results:

Carbide Reamers | |

Chucking Reamers | |

Hand Reamers | |

Machine Reamers | |

Tapered Reamers |

On top of these, other reamer types include:

- Floating reamers

- Spiral flute reamers

- Shell reamers

- Straight-fluted reamers

- Spiral-fluted reamers

Premium Quality Cutting Tools at Competitive Prices

Our cutting tools are expertly manufactured and rigorously tested to enhance machining performance and operational savings.

Key Factors to Consider When Choosing a Reamer

Choosing the right reamer for a high volume precision machining is crucial to achieving precision, efficiency, and longevity for your job.

Below are the key factors to consider when selecting a reamer:

1. Material of Workpiece

Your workpiece material directly affects the reamer’s performance, wear resistance, and cutting efficiency.

With different materials having varying hardness, machinability, and chip formation characteristics, determining your workpiece material is mandatory or other factors to be properly addressed.

For instance:

- Hard workpieces (e.g. stainless steel, titanium) would require reamers made from carbide or cobalt alloys; often with specialized coatings to resist wear and heat.

- Soft materials (e.g., aluminum, brass) need reamers with sharp cutting edges and polished flutes to prevent material buildup for a smooth finish.

- Abrasive materials (e.g., composites, cast iron) will benefit from reamers with wear-resistant coatings and robust geometries to withstand abrasion

2. Hole Size and Depth

Before choosing the type of reamer to work with, one must match the desired hole size. Reamers are available in standard sizes, but custom sizes can also be manufactured.

For deep holes, consider the length of the reamer. Longer reamers are needed for deeper holes, but they may require additional support to prevent deflection or vibration.

3. Reamer Types

The reamer type determines how the tool will be used and its suitability for specific applications.

For example, in manual operations or low-volume repair works, hand reamers are often the ideal work tool. While other reamers like tapered reamers are used for creating tapered holes, such as for Morse tapers or pipe fittings.

4. Flute Design

The flute design of different reamers will affect chip evacuation, surface finish, and reamer rigidity, which are critical for efficient and accurate reaming.

Other than the flute design (e.g. straight flutes or spiral flutes), it is also equally important to consider the number of flutes. More flutes provide a smoother finish but reduce chip space, while fewer flutes allow better chip clearance but may produce a rougher finish.

5. Cutting Edge Geometry

The geometry of the cutting edges determines the reamer’s cutting efficiency, tool life, and surface finish.

There are different angles in various reamers to help you achieve the desired hole. This includes:

- Helix angle

A higher helix angle improves cutting action and chip evacuation but reduces tool strength. This is particularly important in materials like CFRP where efficient chip removal minimizes heat build-up and potential damage. - Rake angle

Positive rake angles reduce cutting forces, while negative rake angles increase tool strength.

However, in CFRP reaming, a study indicated that while rake angle adjustments minimally influence the magnitude of cutting forces, they significantly impact the type of tool wear [3]. Therefore, when selecting a reamer for CFRP, prioritizing the rake angle that produces a favorable wear pattern is crucial for extended tool life, even if force reduction is minimal. - Relief angle

Ensures the reamer does not rub against the workpiece, reducing heat and wear. Similar to the rake angle, research on CFRP reaming has shown that the relief angle’s primary influence is on the form of tool wear.

Selecting an appropriate relief angle is critical to prevent detrimental wear patterns, such as wavy cutting edges, which can compromise surface finish and tool longevity in CFRP applications.

6. Cost and Tool Life

For machinists, balancing cost and tool life is essential for economic efficiency of your workplace.

Higher-quality reamers made from tougher materials like carbide or coated reamers may have a higher upfront cost but offer longer tool life and better performance.

Therefore, before purchasing a reamer, it is crucial to put the total cost of ownership, including replacement frequency and downtime into consideration too.

How to Use Reamers: A Step-By-Step Guide

Reaming, while a common machining process, is a specialized task that demands skill and precision.

To achieve the best results, it’s essential to follow the correct procedure tailored to the reamer’s size, type, and specific job requirements:

1. Select the Right Reamer

Begin by choosing the appropriate reamer based on the workpiece material, hole size, tolerance requirements, and application. Ensure the reamer diameter matches the desired hole size, accounting for any material expansion or contraction during machining.

2. Prepare the Workpiece

Secure the workpiece firmly in a vise, chuck, or fixture to prevent movement during reaming. Before you start working on it, ensure the workpiece is clean and free of burrs or debris that could affect the reaming process.

3. Pilot Hole Marking & Drilling

After securing the workpiece, you’ll need to mark the center of the hole and use a spot drill or countersink to create a guiding indentation. This ensures precise alignment for the drill bit in the next step.

For optimal drilling, particularly in varying materials, select a drill point angle between 118° and 140° or greater, and always initiate the process with a pilot hole slightly undersized relative to the final desired diameter [4].

The pilot hole should typically be within 0.1–0.5 mm (0.004–0.020 inches) of the reamer size, depending on the material and reamer type.

Use a sharp drill bit and ensure the hole is straight and properly aligned to provide a good starting point for the reamer.

4. Apply Cutting Fluid or Lubricant

Apply an appropriate cutting fluid or lubricant to the reamer and workpiece to reduce heat, improve surface finish, and extend tool life.

For example, use water-soluble oils for steel, kerosene for aluminum, and specialized coolants for exotic materials. Proper lubrication ensures smoother cutting and prevents tool wear.

5. Start Reaming

Insert the reamer into the pilot hole and begin the reaming process. For hand reaming, turn the reamer clockwise using a tap wrench, applying steady, even pressure. Avoid reversing the reamer during the process, as this can damage the cutting edges.

For machine reaming, start the machine at the recommended speed and feed rate, then slowly feed the reamer into the hole while ensuring it remains aligned.

6. Cleaning

Clean the reamer and workpiece to remove any chips, debris, or cutting fluid. Store the reamer in a clean, dry place to prevent rust or damage.

Proper cleaning and storage help maintain the reamer’s performance and extend its lifespan such as by storing them in a controlled environment away from factors like humidity, temperature, and exposure to corrosive chemicals [5].

Understanding the Key Differences: Reaming vs. Drilling vs. Boring in Machining Processes

Understanding the distinctions between reaming, drilling, and boring can be challenging for those new to machining.

This table highlights the key differences between reaming, drilling, and boring, which are essential processes in machining and manufacturing:

| Definition | A process of finishing or sizing a hole to achieve precise dimensions and a smooth surface. | A process of creating a hole in a workpiece using a rotating cutting tool. | A process of enlarging or refining an existing hole to achieve precise dimensions and alignment. |

| Purpose | To improve the accuracy, surface finish, and size of an existing hole. | To create a new hole in a workpiece. | To enlarge, straighten, or improve the accuracy of an existing hole. |

| Tool used | Reamers | Drill bit | Boring head or boring bar |

| Tolerance | High precision; achieves tight tolerances (e.g., ±0.0005 inches). | Lower precision; typically requires further finishing for tight tolerances. | High precision; improves hole alignment and size accuracy. |

| Surface finish | Produces a very smooth surface finish. | Produces a rougher surface finish compared to reaming. | Produces a smoother surface finish than drilling but may require reaming for finer finishes. |

| Application | Used after drilling or boring to achieve final dimensions and finish. | Used to create initial holes in materials. | Used to correct or enlarge holes, often in machining operations. |

Improve Your Bottom Line with Efficient CNC Solutions!

Reamers are precision tools designed to refine and perfect holes, ensuring exceptional accuracy and smooth finishes. Whether you’re working on intricate prototypes or high-volume production, the right reaming process can make all the difference.

Discover how Kota Cutting Tools can bring your projects to life with precision and efficiency. Let’s collaborate to turn your ideas into reality—connect with us today to explore the possibilities!

FAQ

When is it important to ream a pipe?

Reaming a pipe is important in several scenarios where precision, smoothness, and proper fit are critical. Here are the key situations when reaming a pipe is necessary:

- After sawing or cutting to remove burrs, rough edges, or uneven surfaces.

- Preparation for joining and fitting especially in plumbing, hydraulic, or pneumatic systems.

- Improving fluid or gas flow characteristics (e.g., pipelines, HVAC systems) by removing irregularities inside the pipe that could cause turbulence, pressure drops, or blockages.

- Meeting strict dimensional and surface finish standards in industries like aerospace, automotive, or manufacturing.

- Preventing corrosion or wear due to uneven surfaces or burrs inside a pipe where debris or moisture can be trapped.

What are the advantages and disadvantages of reamers?

While reamers offer several advantages, outweighing the cons, they also have some limitations. Here’s a breakdown of the advantages and disadvantages of reamers:

(a) Advantages

- High precision

Reamers are designed to achieve tight tolerances, often within ±0.0005 inches, making them ideal for applications requiring exact hole dimensions.| - Superior surface finish

Reaming produces a smooth, polished surface inside the hole, which is critical for applications involving moving parts, seals, or fluid flow. - Improved hole geometry

Reamers correct irregularities in hole shape, such as out-of-roundness or taper, ensuring a perfectly cylindrical hole. - Versatility

Reamers are available in various types (e.g., hand reamers, machine reamers, adjustable reamers) and can be used on a wide range of materials, including metals, plastics, and composites. - Extended tool life

Since reamers remove minimal material, they experience less wear compared to drills or boring tools, leading to longer tool life.

(b) Disadvantages

- Limited material removal

Reamers are not designed for removing large amounts of material. They are finishing tools and require a pre-drilled or pre-bored hole close to the final size. - Costly

High-quality reamers, especially those made from carbide or coated materials, can be expensive compared to drills or other cutting tools. - Specialized use

Reamers are not suitable for creating holes from scratch. They require a pre-existing hole, which adds an extra step to the machining process. - Limited to straight holes

Standard reamers are designed for straight, cylindrical holes. Specialized tools are required for tapered or non-cylindrical holes.

What are the benefits of finishing a hole with a reamer?

Finishing a hole with a reamer offers several significant benefits, particularly in applications where precision, surface quality, and functionality are critical such as by:

- Reducing the damage risk of components that are fragile during assembly.

- Extending the durability and lifespan of the parts.

- Ensuring uniformity across multiple holes especially for mass production and interchangeable parts in manufacturing.

References

[1] Noah Harrison. Types of Holes in Engineering: A Detailed Guide. Rapid Direct. [Internet] 2024 [cited 2024 Nov 20]. Available from: https://www.rapiddirect.com/blog/types-of-holes/

[2] Zhang Y, Wang Y, Han Z. Study on Characteristics for Reaming Titanium Alloy Ti6Al4V with Two Kinds of Cemented-Carbide Groove Reamers. Materials. 2022; 15(14):5027. https://doi.org/10.3390/ma15145027

[3] Sauer K, Putz M. Reaming of carbon fibre reinforced plastics: Influence of tool geometry on process forces and tool wear. Procedia CIRP. 2021;99:409-413. Available from: https://doi.org/10.1016/j.procir.2021.03.058

[4] Tom Pyle. Spot Drilling: The First Step to Precision Drilling. Harvey Performance. [Internet] 2022 [cited 2022 Aug 25]. Available from: https://www.harveyperformance.com/in-the-loupe/choosing-spot-drill/

[5] Maintenance Tips for Drilling Reamers: A Practical Guide for the Oil and Gas Industry. Ed-Projects. [Internet] Available from: https://ed-projects.com/maintenance-tips-for-drilling-reamers/

Acquire Premium Quality Cutting Tools at Exceptional Prices with Kota Cutting Tools

Our cutting tools are expertly manufactured and rigorously tested by our technical team to enhance your machining performance and take your business to new heights.