High-Precision Machine Reamers for Accurate Hole Finishing

Need accurate and consistent hole finishing? Kota Cutting Tools supplies a wide range of machine reamers in Malaysia designed for precision metalworking applications. Our reamers deliver tight tolerances, excellent surface finish, and superior roundness — ideal for manufacturing, mold & die, automotive, aerospace, and general engineering use.

We offer HSS and carbide reamers in various flute styles and diameter ranges, suited for reaming mild steel, stainless steel, cast iron, aluminium, and other engineering materials.

What Is Machine Reamer

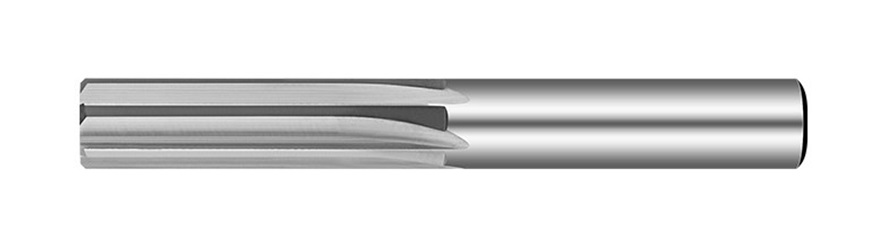

A machine reamer is a rotary cutting tool used to enlarge and finish a pre-drilled hole with high accuracy and surface quality. Unlike drill bits, which create rough or slightly undersized holes, machine reamers refine the final diameter and achieve superior roundness and surface finish.

Our Selection of Machine Reamers

A wide selection of cutting tools catering to the diverse needs of industries in Malaysia. Whatever your application, we have the perfect tool for you.

High-Speed Steel Machine Reamers

Solid Carbide Machine Reamers

Choosing the Right Cutting Tools

Not sure which tool suits your application? Talk to our technical team today or request a quote for the perfect cutting tools for your application.

FAQ

What is the difference between a machine reamer and a drill bit?

A drill bit is used to create the initial hole, while a machine reamer is used to refine the hole, making it more accurate in size and smoother in finish. Machine reamers do not remove as much material as drills but offer much tighter tolerances.

What brands of machine reamers do you carry?

We offer reamers from trusted manufacturers like Somta Tools, known for their precision and durability. Whether you’re looking for parallel shank, taper shank, or solid carbide options, Somta has a solution for various industrial needs.

How do I choose a machine reamer?

Choosing the right machine reamer depends on several factors, including the type of hole (through or blind), the material you’re working with, the required surface finish, and the tolerance level.

For blind holes or softer materials like aluminium, spiral flute reamers are ideal. For through holes or short reaming operations, straight flute reamers are typically sufficient. Material hardness and machine type (CNC, lathe, manual) should also guide your selection.

What material is a machine reamer made of?

Most machine reamers are made of High-Speed Steel (HSS) or carbide. HSS reamers are known for their toughness and versatility across a wide range of materials.

Carbide reamers, on the other hand, are harder and more wear-resistant, making them suitable for high-speed, high-precision applications—especially in harder materials like stainless steel or alloys.

What are the 3 types of machine reamers?

The three common types of machine reamers are straight flute reamers, spiral flute reamers, and taper reamers. Straight flute reamers are ideal for general-purpose and through-hole applications, while spiral flute reamers are designed for blind holes, offering better chip evacuation. Taper reamers are used to create or finish tapered holes for applications like fitting taper pins or aligning components.

Should I choose an HSS reamer or a carbide reamer?

Your choice depends on the material you’re working with and the level of precision required. HSS reamers are more affordable and suitable for general-purpose use on softer metals such as mild steel, aluminium, or brass.

Carbide reamers, while more expensive, provide longer tool life and superior performance in harder materials, offering better heat resistance, surface finish, and dimensional control—especially in high-speed production settings.

Do I need a revolving center when using machine reamers on a lathe?

Yes, using a revolving center is highly recommended when reaming on a lathe, particularly for longer or more flexible workpieces. It provides support to the tail end of the workpiece, reducing vibration and preventing deflection. This stability helps maintain alignment and improves both the accuracy and surface quality of the finished hole.

What are the differences between taper shank, taper bridge, and taper pin reamers?

Taper shank reamers have a conical shank (typically Morse taper) that fits directly into the machine spindle, providing a secure, self-locking fit for industrial machines.

Taper bridge reamers are designed for enlarging holes in structural steel or bridgework and often feature a pilot tip for better centering.

Taper pin reamers, on the other hand, are specifically used to finish holes that will accommodate taper pins—commonly used in mechanical assembly for alignment or locking purposes. Each type serves a distinct purpose based on the hole geometry and application.